Aluminum Spacer Bending Machine

- KING TECH

- CHINA

- 10 DAYS

- 50 SETS/MONTH

Aluminum spacer automatic bending machine solve the IG unit production spacer accuracy bending, shape angle bending and fast speed production problems.

Full auto spacer production , include auto loading, auto length detection, auto bending and auto cutting. Save much time and more safe on real production.

Servo system with Plc controller to keep high speed and accuracy spacer production time, to support desiccant and butyl steps.

KT-B Series Automatic Aluminum Spacer Bending Machine For Insulating Glass Production

Introduction

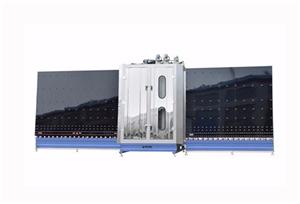

KT-B01 Full-Automatic Aluminum spacer bending machine

Features

KT-B01 aluminum spacer bending machine could finish square,rectangle, circle, triangle, polygon, irregular etc... shapes production.

PLC control system,Servo motors control auto feeding system, practical interface, easy to operate.

Applicable to any width spacer, also support to any shape continuous bending.

Bending lateral adopts split stainless steel shield. Spacer automatic welding function.

Technical Parameters

| Model | KT-B01 Auto Spacer Bending Machine |

| Voltage | 380/480 V 50/60 Hz |

| Total Power | 4.5 KW |

| Air Pressure | 0.5-0.8 Mpa |

| Max Bending Size | 2000×2000 mm |

| Min Bending Size | 250×250 mm |

| Spacer Width | 5.5-22 mm |

| Total Weight | 1500 kg |

| Dimensions | 10500×2100×2600 mm |

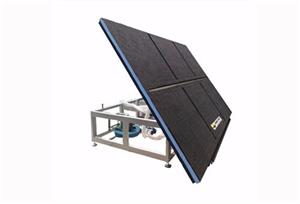

KT-B02 Automatic Aluminum spacer bending machine

Features

Solve the water/air leakage of four angles, which are the main leakage channels of insulating glass.

Prolong the life of insulating glass , saving connections.

Enhance the production efficiency of aluminum frame.

The whole hardness and horizontal is better, easier for butyl coating and sheet laminating.

Technical Parameters

| Model | KT-B02 Spacer Bending Machine |

| Voltage | 380/480 V 50/60 Hz |

| Total Power | 2.5 KW |

| Air Pressure | 0.5-0.8 Mpa |

| Max Bending Size | 2000×2000 mm |

| Min Bending Size | 250×250 mm |

| Spacer Width | 5.5-22 mm |

| Total Weight | 400 kg |

| Dimensions | 4000×2060×2700 mm |