Insulating Glass Production Machine

-

Hot

Vertical Silicone Sealing Robot

KT-VS Series Vertical Style automatic sealing machine with optimised sealant application, especially around corners.

In order to increase the overall quality of the final product, we focused on the machine‘s degree of soiling when developing the CleanSeal.

KING TECH supplied more than 350 sets vertical style insulating glass silicone sealing robot over the world, to support customer on IG unit production for easy seal.automatic IG unit silicone sealing robot vertical style two-componet silicone sealing robot insulating glass silicone sealing robotEmail Details -

Hot

Butyl Rubber Coating Machine

KT-BM Series Butyl extruder for precision Butyl coating on both sides of spacers.

Email Details

Sensor-controlled guide Rollers ensure optimal stabilization of the frame and thus enable even coating.

Opening and closing of the coating nozzles for each frame side are controlled automatically.

The integrated measurement device for frame widths ensures continuous nozzle adjustment from

6 to 24 mm.

The coating speed can be set individually.

The butyl coating machine with high-precision is designed to evenly coat both sides of spacer frames with Butyl. -

Hot

Aluminum Spacer Bending Machine

Aluminum spacer automatic bending machine solve the IG unit production spacer accuracy bending, shape angle bending and fast speed production problems.

Full auto spacer production , include auto loading, auto length detection, auto bending and auto cutting. Save much time and more safe on real production.

Servo system with Plc controller to keep high speed and accuracy spacer production time, to support desiccant and butyl steps.automatic aluminum spacer bending machine semi-auto aluminum spacer bending machine insulating glass production aluminum spacer bending machineEmail Details -

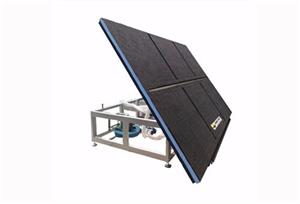

Other IG Production Equipments

Insulating glass auxiliary equipments are for semi-auto or manually production IG unit.

Email Details

All machines with good quality and high accuracy. -

Hot

Desiccant Dryer Filling Machine

Full automatic on insulating glass production desiccant dryer filling. Include auto driller, auto filling and auto sealing for aluminum spacer.

Email Details

Suitable any size, angle and width aluminum spacer.

PLC controller with Pneumatic pedal control to keep high accuracy and quality, also more safe and easy for staff. -

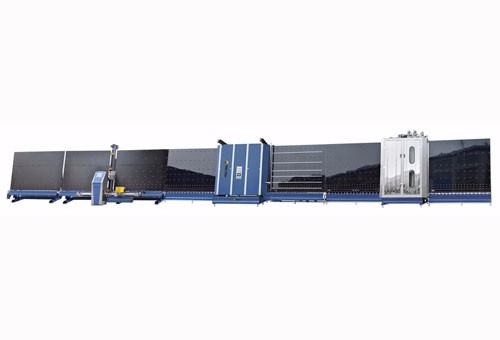

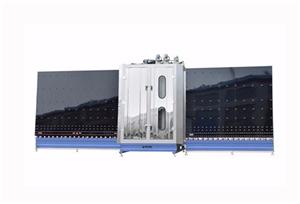

Full Automatic Insulating Glass Production Line

Full automatic Insulating glass production line adopts the most advanced IG manufacture technology and craft in the world. It has all functions of inner-panel assembly and stepped glass process.

Email Details

The line can process double unit,triple unit and step unit with high efficiency.The assembly optional auto gas filling press keeps both gas loss and cycle times low. At the end of the line, the sealing station ensures stability and above all perfect corners.Final auto seal machine perfect to finish whole insulating glass production to save much more time and cost on IG production. -

Two-component Silicone Pump

KT-SP Two component Silicone pump is the production of IG unit curtain wall to play with aluminum spacer, sealed in the realization of A,B groups were mixed.

Email Details

Particularly suited to the requirements of the ratio of precision plastic kind of harsh for doors and windows and walls of glass deep processing enterprises efficient, high-quality, high pass rate of the production line operating needs.

The silicone pump broke through the traditional structures. Rack used welding as a whole, the increase in the gantry, welding triangle pose a stable structure, work to over-come the cantilever shake; B double-pump column, two-platen sealing Road, and solve the group were easy to glue oxide leakage problem; optimizing control Road design, to keep fast flow of similar products. -

Horizontal Silicone Sealing Robot

KT-HS01 Horizontal Sealing robot is an economical and practical two-component silicone sealing machine, which is more and more popular in normal or small IG unit production factory.

Email Details

Whole machine easy use and maintaince, sensor position system to keep high accuracy on IG unit seal.

Hydralic support pump to keep all air support and sealing arc on perfect performance.