CNC Woodworking Center

- KING TECH

- CHINA

- 15-25 DAYS

- 50 SETS/MONTH

cnc woodworking center is a practical and industry type woodworking machine.

CNC Woodworking Center

Instroduction

KT-M Series Vantage Five -Axis Machining Center

Features

An extremely heavy-duty five-axis machining center with OSAI controller—designed for the most demanding processing requirements. Maximum precision, easy operation, and productive efficiency.

CNC machining center with 5 synchronizing interpolated axes; Real-Time Tool Center Point Rotation (RTCP); Z axis height can be extended to cater for extra-large and extra-thick 3D processing.

CNC machining center with 5 synchronizing interpolated axes; Real-Time Tool Center Point Rotation (RTCP); Z axis height can be extended to cater for extra-large and extra-thick 3D processing.

Working speed, travelling speed and cutting speed can all be controlled separately, dramatically improve productivity and finish quality.

Technical Parameters

SERIES | KT-M2040 | KT-M2550 | KT-M3060 |

Traveling Size | 4800*2800*2000/2400 mm | 5800*3300*2000/2400 mm | 6800*3800*2000/2400 mm |

A/C Axis | A: ±120° C:±245° | ||

Working Size | 4000*2000*1600/2000 mm | 5000*2500*1600/2000 mm | 6000*3000*1600/2000 mm |

Transmission | X/Y/Z Rack and Pinion Drive | ||

Spindle Power | 10/15 KW | ||

Spindle Speed | 22000 r/min | ||

Traveling Speed | 40/40/10 m/min | ||

Working Speed | 20 m/min | ||

Tool Magzine | Linear | ||

Tool Slots | 8 | ||

Driving System | Delta/Yaskawa | ||

Voltage | AC380/50 Hz | ||

KT-G Series Venture Five-Axis Machining Center

Features

A heavy-duty five-axis machining center equipped with world-renowned controller-designed for the most demanding processing requirements. Maximum precision, faster production.

Features world top class components.

CNC machining center with 5 synchronizing interpolated axes; Real-time Tool Center Point Rotation (RTCP), well suited for 3D curved surface processing.

Working speed, travelling speed and cutting speed can all be controlled separately, which dramatically improve productivity and finish quality.

Technical Parameters

SERIES | KT-G1224 | KT-G1530 | KT-G2030 |

Traveling Size | 1850*3100*950/1300 mm | 2150*3700*950/1300 mm | 2650*3700*950/1300 mm |

A/C Axis | A:±120°,C:±245° | ||

Working Size | 1200*2400*650/1000 mm | 1500*3000*650/1000 mm | 2000*3000*650/1000 mm |

Table Size | 1200*2400 mm | 1550*3050 mm | 2100*3050 mm |

Transmission | Y rack and pinion drive, X/Z ball screw drive | ||

Spindle Power | 10/15 KW | ||

Spindle Speed | 22000 r/min | ||

Traveling Speed | 60/60/20 m/min | ||

Working Speed | 20 m/min | ||

Tool Magzine | Carousl | ||

Tool Slots | 8 | ||

Driving System | Delta/Yaskawa | ||

Voltage | AC380/50 Hz | ||

KT-T Series Mini Five-Axis Machining Center

Features

Twin table design doubles the productive efficiency by allowing loading and unloading operations on one station without interrupting the work cycle.

An entry-level five-axis machining center with world top-class controller — designed for the most demanding processing requirements, maximum precision, and all-round excellece.

Features world top class components.

CNC machining cent er with 5 synchronizing interpolated axes; Real-Time Tool Center Point Rotation (RTCP), well suited for 3D curved surface processing.

Technical Parameters

SERIES | KT-T1212 | KT-T1224 |

Traveling Size | 1720*1820*750 mm | 1720*3040*750 mm |

Working Size | 1220*1220*500 mm | 1220*2440*500 mm |

Table Size | 1230*1220 mm | 1230*2440 mm |

A/C Axis | A:±185° C:±320° | |

Transmission | X/Y Rack and Pinion Drive, Z Ball Screw Drive | |

Spindle Power | 8.5 KW | |

Traveling Speed | 60/60/20 m/min | |

Working Speed | 20 m/min | |

Tool Magzine | Carousel 8 Slots | |

Driving System | Delta/Yaskawa | |

KT-D Series Center for Mold Industry

Features

Features self-lubricating, life-long maintenance-free Japanese guide rail.

Italian high-speed spindle,with top speed of 10000 RPM,guaranteeing maximum processing efficiency and productivity.

Whole working table cast by resin sand. The annealing and other heat treatment methods ensure that the whole structure is tested to the limit for sturdiness and reliability.

Technical Parameters

SERIES | KT-D1525 | KT-D2040 | KT-D2450 |

Traveling Size | 2500*1500*800 mm | 4000*2000*800 mm | 5000*2400*800 mm |

Transmission | X/Y racn and pinion drive, Z ball Screw drive | ||

Traveling Speed | ≥16000 mm/min | ||

Working Speed | ≥10000 mm/min | ||

Spindle Power | 7.5 / 9.6 KW | ||

Spindle Speed | 18000 r/min | ||

Driving System | Yaskawa | ||

Voltage | AV380 V/50 Hz | ||

Controller | Delta/Syntec | ||

KT-E Series Four-Axis Machining Center

Technical Parameters

SERIES | KT-E Four Axis |

Traveling Size | 2500*1260*420 mm or 3100*2100*420 mm |

Transmission | X/Y rack and pinion drive, Z ball screw drive |

Traveling Speed | ≥45000 mm/min |

Working Speed | ≥20000 mm/min |

Spindle Power | 9.6 KW |

SPindle Speed | 24000 r/min |

Driving System | Yaskawa |

Controller | Delta/Syntec/Osai |

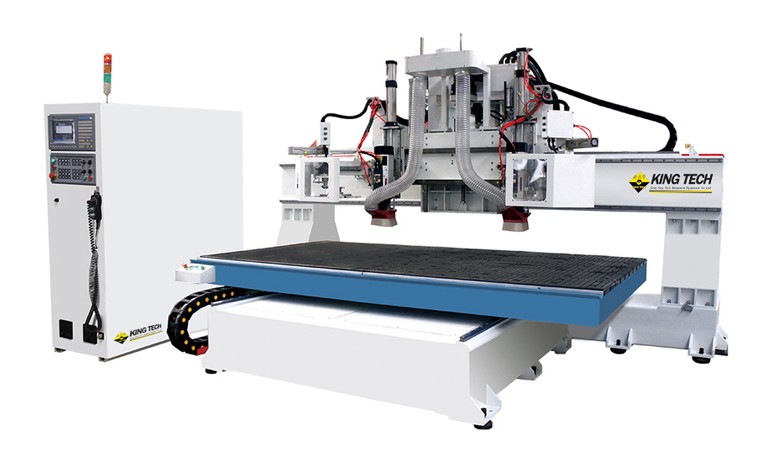

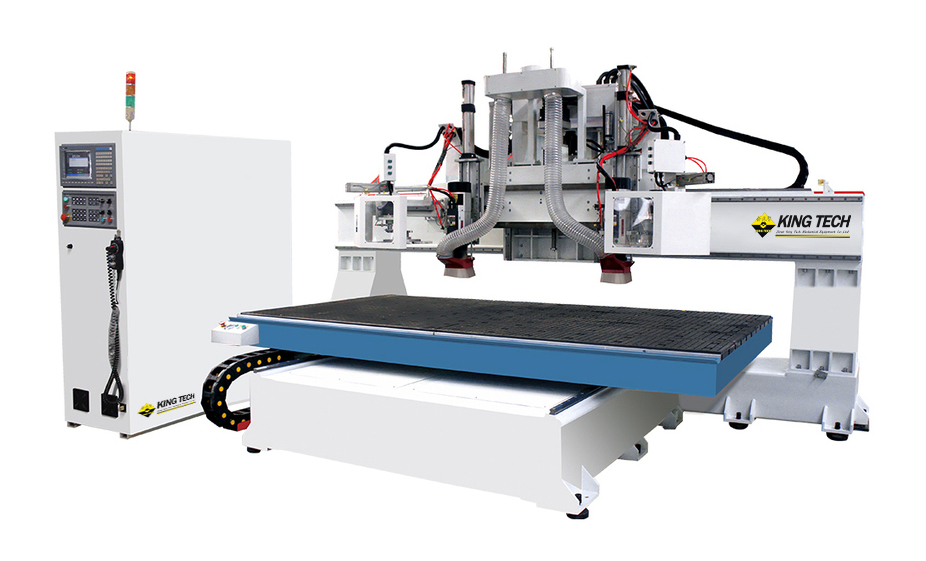

KT-L Moveable Table Work Center

Features

Double spindles, and double tool magazines enable synchronous operation. Extremely heavy-duty with a moveable bed.

Two heads can work individually, or do the same job simultaneously — more than doubles the efficiency!

Rapid switch between the two heads for different applications helps to save your precious time and enhance flexibility and value.

Two tool magazines up to 16 slots multiply your choices and cater to your appetite for variety.

Features world top mechanical and electronic components, e.g. German vacuum table and transmission system, Japan servo driver, Italian spindle.

Working speed, travelling speed and cutting speed can all be controlled separately, dramatically improve productivity and finishing quality.

Versatile functions: engraving, routing, drilling, cutting, milling, side drilling, side milling, side sawing, etc. Boring unit optional. Robust, all-round, highly efficient.

Technical Parameters

SERIES | KT-L1530D | KT-L3020D |

Traveling Size | 1600*3100*250 mm | 3040*2040*250 mm |

Working Size | 1550*3050*200 mm | 3000*2000*200 mm |

Table Size | 1530*3050 mm | 3050*1980 mm |

Transmission | X/Y rack and pinion drive;Z ball screw drive | |

Table Structure | Vacuum Table | |

Spindle Power | 9.6/12 KW | |

Spindle Speed | 24000 r/min | |

Traveling Speed | 60 m/min | |

Working Speed | 20 m/min | |

Tool Magazing | Carousel | |

Tool Solts | 8*2 | |

Driving System | Yaskawa | |

Voltage | AC380/50 Hz | |

Controller | Delta/OSAI/Syntec | |

KT-A Series Heavy-Duty Work Center

Features

Extremely heavy-duty, with an 8 slots carousel tool changer, Accurate and rapid tool positioning.

Versatile: routing, drilling, cutting, side milling, edge chamfering, etc.Boring unit optional.

Features world top class mechanical and electronic components, e.g. Japanese servo driver and gear reducer, Italian high power automatic tool changing spindle, French low-voltage electrical components, which guarantee stable performance and high finish quality.

T-slot vacuum table with great absorption strength — absorb on multi-zone or clamp with pop-up positioning pin, it is your call.

Drilling head , Pop-up position pins optional.

Technical Parameters

SERIES | KT-A1224 | KT-A1530 | KT-A2030/2040 |

Traveling Size | 2500*1260*330 mm | 3100*1570*330 mm | 3350*2100*330 mm 4350*2100*330 mm |

Working Size | 2480*1240*200 mm | 3080*1560*200 mm | 3050*2032*200 mm 3940*2032*200 mm |

Table Size | 2500*1240 mm | 3100*1570 mm | 3100*2100 mm 4020*2100 mm |

Optional Working Length | 2850/5000/6000 mm | ||

Transmission | X/Y rack and pinion drive;Z ball screw drive | ||

Table Structure | Vacuum Table | ||

Spindle Power | 9.6/12 KW | ||

Spindle Speed | 24000 r/min | ||

Traveling Speed | 80 m/min | ||

Working Speed | 20 m/min | ||

Tool Magzine | Carousel | ||

Tool Slots | 8 | ||

Driving System | Yaskawa | ||

Controller | Delta/Syntec/OSAI | ||

KT-R Series Venture Work Center

Features

An entry-level all-rounder, choose your tool changer, linear or carousel, extraordinary solution with competitive price.

Using world-class components, e.g. HSD 9.6 KW ATC spindle, Japan Yaskawa servo motor driving system,Japan Shimpo gear reducer, Schneider low voltage electrical components, Delta inverter—guaranteeing optimum performance and minimum failure.

Versatile functions: routing, drilling, cutting, side-milling, edge chamfering, etc.

Pusher optional.

Technical Parameters

SERIES | KT-R1325 | KT-R1530 | KT-R2030/2040 |

Traveling Size | 2500*1260*200 mm | 3100*1570*200 mm | 3100*2060*200 mm 4030*2060*200 mm |

Working Size | 2480*1230*180 mm | 3080*1560*180 mm | 3080*2050*180 mm 4000*2050*180 mm |

Table Size | 2500*1230 mm | 3100*1560 mm | 3100*2050 mm 4030*2050 mm |

Optional Working Length | 2850/5000/6000 mm | ||

Transmission | X/Y Rack and Pinion; Z Ball Screw Drive | ||

Table Structure | Vacuum Table | ||

Spindle Power | 9.6 KW | ||

Traveling Speed | 45 m/min | ||

Working Speed | 20 m/min | ||

Tool Magzine | Carousel | ||

Tool Slots | 8 | ||

Driving System | Yaskawa | ||

Voltage | AV380/50 Hz | ||

Controller | Delta/Syntec/OSAI | ||

KT-V Series ATC Product

Features

High-performance all-round machinery with extraordinary value, but at a very economical price. With linear tool changer, constructed with world-class components, consistent high performance.

Featuring Italian high frequency air-cooling electronic spindle and world-class servo motor and driving system.

Vacuum table using high-density (1.3-1.45 g/cm) material with great suction strength, comfortably accommodating all sizes of work piece.

Syntec controller — enabling this product to accomplish multi-layer 3D job, cutting, engraving, milling, all at ease.

Technical Parameters

SERIES | KT-V1325 | KT-V1530 | KT-V2030/2040 |

Traveling Size | 2500*1260*200/300 mm | 3100*1570*200/300 mm | 3100*2100*200/300 mm 4200*2100*200/300 mm |

Working Size | 2480*1230*200/300 mm | 3080*1550*180/280 mm | 3080*2050*180/280 mm 4000*2050*180/280 mm |

Table Size | 2480*1230 mm | 3100*1560 mm | 3100*2050 mm 4020*2050 mm |

Optional Working Length | 3000/5000/6000 mm | ||

Transmission | X/Y Rack and Pinion; Z Ball Screw | ||

Table Structure | T-Slot Vacuum | ||

Spindle Power | 4.5/9.6 KW | ||

Spindle Speed | 24000 r/min | ||

Traveling Speed | 40 m/min | ||

Working Speed | 18 m/min | ||

Driving System | Yaskawa | ||

Voltage | AC380/50 Hz | ||

Controller | Delta/Syntec/OSAI | ||