Corner Cleaning Machine

- KING TECH

- CHINA

- 15-25 DAYS

- 50 SETS/MONTH

KT-CK Series PVC & uPVC profile corner cleaning machine is very high accuracy and stable corner cleaning equipment.

Corner Cleaning Machine

Introduction

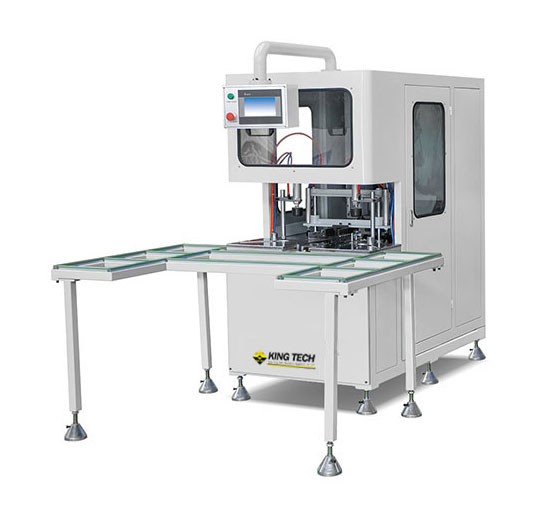

KT-CK-CNC01 Corner Cleaning Machine

Features

KT-CK-CNC01 Corner Cleaning Machine is mainly used to clean up and down surface & outside welding slags.

Suitable for mass production of different profiles.

Imported CNC control system be adopted, can set up two-dimension processing programs according to different profile.

More than 100 programs could be stored.

Processing programs could be corrected according to spot situation, so welding seams with error could be cleaned efficiently.

Technical Parameter

Power supply | 220/380 V 50/60 Hz |

Milling cutter rotary speed | 2800 r/min |

Air consumption | 80 L/min |

Profile width | 20~120 mm |

Weight | 700 kg |

Input power | 5 KW |

Air pressure | 0.5-0.8 MPa |

Profile height | 25~90 mm |

Overall dimension | 1570x2670x2070 mm |

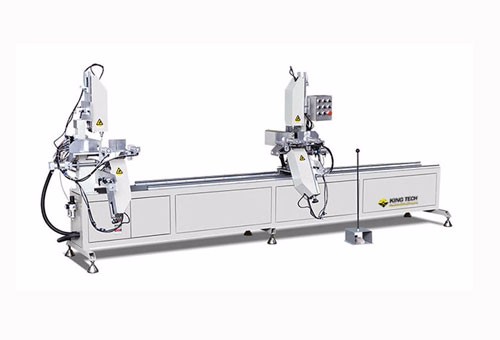

KT-CK-CNC02 Corner Cleaning Machine

Features

KT-CK-CNC02 Corner Cleaning Machine is a professional used in cleaning the welding tumor in 90°corner of external for window frame and sash, the upper and lower of profile as well as the groove of rubber strip.

Two-axis CNC cleaning the corner of processing flow controlling make the operation is easy.

Adopts industry grade computer system, closed-loop controlling, ensures high precision.

Interface in figures and diagrams which can display directly the moving trace of the cutter.

It is simple, direct-viewing with the demonstrating program function, can set two-dimension processing programming by CNC controller.

Equipped with USB connection, may connect with external store.

The value can be stochastic keyed, revised the processing program on the spot, so that make the welding seam error can be cleaned up efficiently.

Adopt the dust-cleaner which can clean the dust so that ensure the operator health.

Technical Parameter

Power supply | 220/380 V 50/60 Hz |

Millinf cutter rotary speed | 2800 r/min |

Air consumption | 60 L/min |

Profile width | 20-120 mm |

Weight | 650 kg |

Input power | 3 KW |

Air pressure | 0.5-0.8 MPa |

Profile height | 30-120 mm |

Overall dimension | 2000x1820x1500 mm |

KT-CK06 Corner Cleaning Machine

Features

KT-CK06 Corner Cleaning Machine mainly applies to corner cleaning for PVC profiles, once can clean the welding slag on top and bottom.

It has characteristics of high reliability, efficiency and accuracy.

Technical Parameter

Power supply | 220/380 V 50/60 Hz |

Milling cutter rotary speed | 2800 r/min |

Air consumption | 15 L/min |

Profile width | 30-120 mm |

Weight | 120 kg |

Input power | 0.2 KW |

Air pressure | 0.5-0.8 MPa |

Profile height | 25-120 mm |

Overall dimension | 1050x670x1370 mm |

KT-CK08 Corner Cleaning Machine

Features

KT-CK08 Corner Cleaning Machine professional used in cleaning the welding seam in 90°and " V " shape of PVC win-door.

The worktable sliding rail ensures the mullion in accurate location.

The special pneumatic compaction device make the profile under the good force so that ensure the quality of cleaning.

Upper and lower planning cutter is driven by pneumatic.

Both hand concurrent operation button, ensures the oprator safety.

Technical Parameter

Power supply | 220/380 V 50/60 Hz |

Milling cutter rotary speed | 2800 r/min |

Air consumption | 15 L/min |

Profile width | 0-120 mm |

Weight | 112 kg |

Input power | 0.2 KW |

Air pressure | 0.5-0.8 MPa |

Profile height | 40-120 mm |

Overall dimension | 860x650x1120 mm |