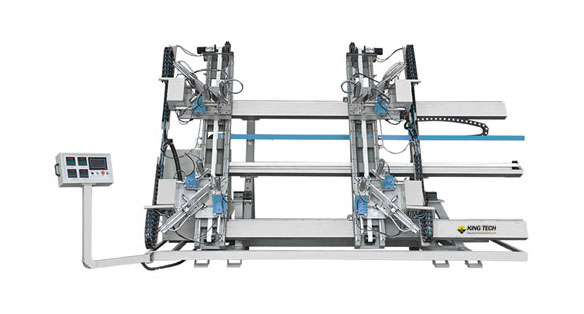

Corner Combining Machine

- KING TECH

- CHINA

- 25-35 DAYS

- 20 SETS/MONTH

KT-CC Series PVC and uPVC profile corner combining machine is full automatic profile corner welding machine.

Easy load and welding corners same time, to save the time and keep high accuracy.

KT-CC Series PVC/UPVC Corner Combining Machine

Introduction

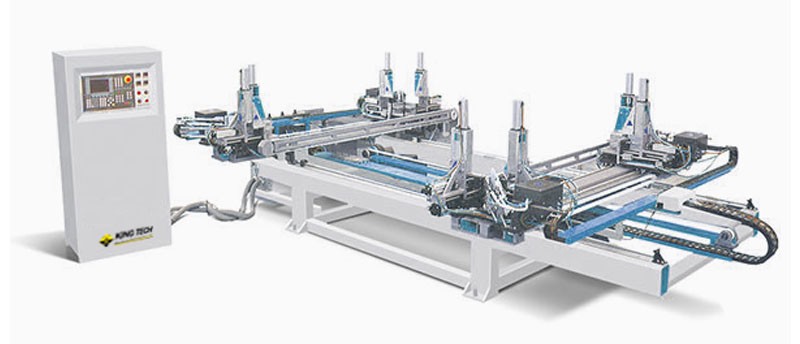

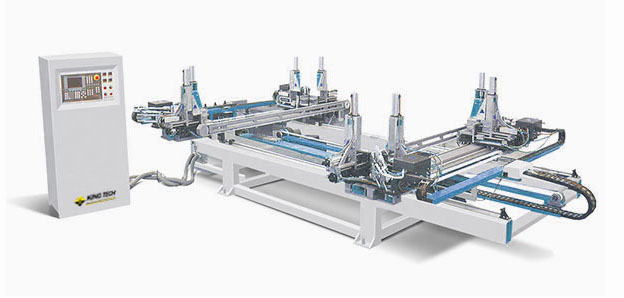

KT-CC-H3000B

Features

KT-CC-H300B PVC/uPVC corner welding machine can one time clamping can realize the welding of the rectangular frame fan products, imported CNC system control, high precision of welding products, can weld multi-layer profiles once, to achieve the micro welding of coextrude profiles.

Technical Parameter

Air pressure | 0.5~0.8 MPa |

Power supply | 380 V/50 Hz |

Welding height | 25~160 mm |

Welding range | 500x650~1800x3000 mm |

Weight | About 3000 kg |

Air consumption | 100 L/min |

Input power | 9 KW |

Welding width(Max.) | 120 mm |

Overall dimension | 5100x3050x1500 mm |

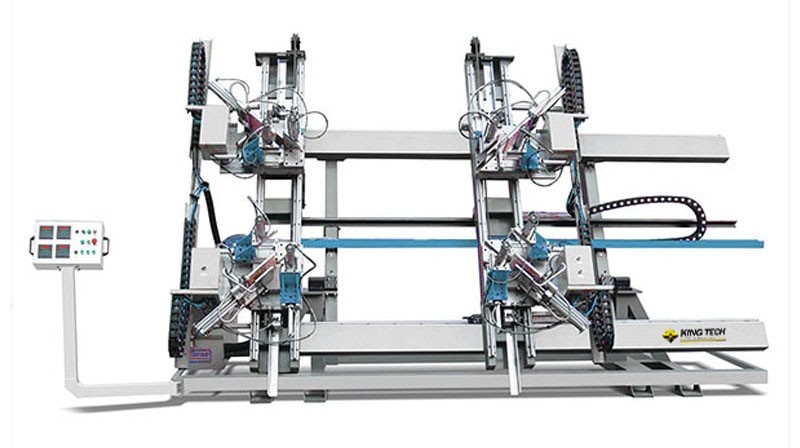

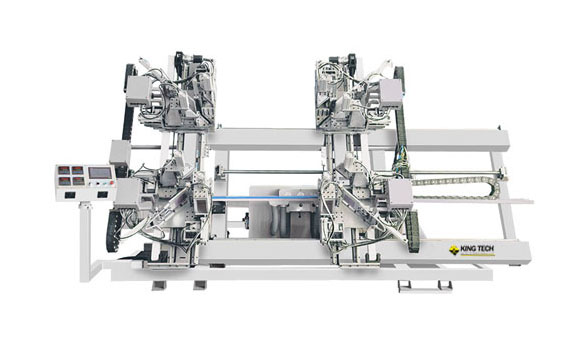

KT-CC-3000G

Features

KT-CC-3000G Full automatic PVC/uPVC corner combining machine suitable for welding PVC profile.

Adopt programmable controller (PLC) ensures the machine running more steady and reliable.

The rectangular frame can be welded at a time,high production efficiency.

High precision linear guiding pair ensured steady and long-term processing accuracy.

Professional mold configuration, can provide the design for different profiles ensure the welding quality.

Pressure protection/ alarm device: to realize the effective quality control should make the machine start and work in normal pressure which strictly conformed to the requirement so as to avoid quality problem and operational safety.

Auto trouble detection.

Technical Parameter

Air pressure | 0.5~0.8 MPa |

Power supply | 380 V/50 Hz |

Welding height | 25~160 mm |

Welding range | 400x400~1800x3000 mm |

Weight | About 3000 kg |

Air consumption | 100 L/min |

Input power | 9 KW |

Welding width(Max.) | 120 mm |

Overall dimension | 5000x2000x2850 mm |

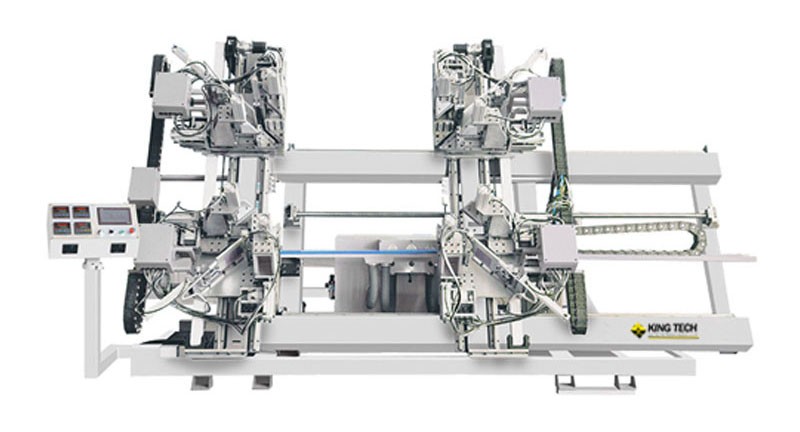

KT-CC-3000A/B

Features

KT-CC-3000A/B corner combining machine suitable for welding PVC profile. Process of processing flow control, operation simply.

Adopts industry grade computer system, closed-loop controlled, high precision and quick shift for cutting size.

Full color computer with touch screen,simple operation, clear displayer and direct viewing.

The rectangular frame can be welded at a time,high production efficiency.

Process of processing flow control, operation simply.

The user can definite the material processing parameter.

Adopt parallel welding technology so as to obtain higher welding strength.

High precision linear guiding pair ensured steady and long-term processing accuracy.

Professional mold configuration, can provide the design for different profiles ensure the welding quality.

Pressure protection/ alarm device: to realize the effective quality control should make the machine start and work in normal pressure which strictly conformed to the requirement so as to avoid quality problem and operational safety.

Technical Parameter

Air pressure | 0.5~0.8 MPa |

Power supply | 380 V/50 Hz |

Welding height | 25~160 mm |

Welding range | 350x350~1800x3000 mm |

Weight | 2600 kg |

Air consumption | 200 L/min |

Input power | 9 KW |

Welding height(Max.) | 120 mm |

Overall dimension | 5000x2000x2850 mm |