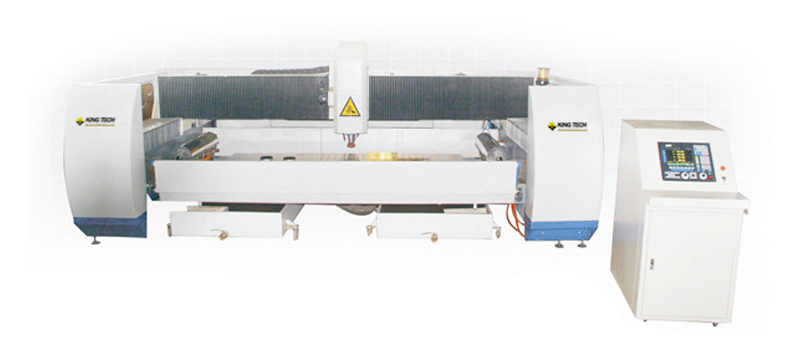

Glass CNC Working Center

- KING TECH

- CHINA

- 15-25 DAYS

- 50 SETS/MONTHThis machine adopts CNC system to control axis X, Y, Z and the main axis of the engraving machine. There is automatic control on lubrication, vacuum, hydraulic pressure, and water supply, also, it has the function of protection and alarm. It is widely used in grinding, cutting, engraving, drilling and polishing glass and mirror. The whole procedure from pattern design to processing is controlled by computer. It can equip tool library and tool changing system according to requirements. Its advantages are: stationary system, high processing speed, easy operation and low price.

This machine adopts CNC system to control axis X, Y, Z and the main axis of the engraving machine. There is automatic control on lubrication, vacuum, hydraulic pressure, and water supply, also, it has the function of protection and alarm. It is widely used in grinding, cutting, engraving, drilling and polishing glass and mirror. The whole procedure from pattern design to processing is controlled by computer. It can equip tool library and tool changing system according to requirements.

Its advantages are: stationary system, high processing speed, easy operation and low price.

Glass CNC Working Center

Instroduction

CNC Glass Working Center

System

CNC control system is provided by the famous European manufacturers;

High processing efficiency: with fast mechanical transmitting, the maximum speed (not in processing on glass) can reach 50 m/min, which is the same speed with the similar machines in Europe.

Easy operation

Having Chinese and English operation interface, it can improve human-computer interaction, customers only use few parameters to reach the normal processing.

Technical Parameters

Model | LDKW1208 | LDKW1210 | LDKW1812 | LDKW2212 | LDKW2515 | LDKW2815 | LDKW3220 | LDKW4525 |

Table Size (mm) | 1200×800 | 1200×1000 | 1800×1200 | 2200×1200 | 2500×1500 | 2800×1500 | 3200×2000 | 4500×2500 |

Stroke of Axis x、y、z (mm) | 1200×800×250 | 1200×1000×250 | 1800×1200×250 | 2200×1200×250 | 2500×1500×250 | 2800×1500×250 | 3200×2000×250 | 4500×2500×250 |

Rotating Angle of Axis | 0.01×0.02×0.01 | 0.01×0.02×0.01 | 0.01×0.02×0.01 | 0.01×0.02×0.01 | 0.01×0.02×0.01 | 0.01×0.02×0.01 | 0.01×0.02×0.01 | 0.01×0.02×0.01 |

Allocating Accuracy(X、Y、Z) (mm) | 0.005×0.01×0.005 | 0.005×0.01×0.005 | 0.005×0.01×0.005 | 0.005×0.01×0.005 | 0.005×0.01×0.005 | 0.005×0.01×0.005 | 0.005×0.01×0.005 | 0.005×0.01×0.005 |

Velocity(Axis X.Y)(m/min) | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 | 15-35 |

Speed of Axis Z(m/min) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

Rotating Speed of Main Spindle Speed(rpm) | 0-9000 | 0-9000 | 0-9000 | 0-9000 | 0-9000 | 0-9000 | 0-9000 | 0-9000 |

CNC System | USA | USA | USA | USA | USA | USA | USA | USA |

Main Spindle Power(KW) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Glass Thickness(mm) | 2-30 | 2-30 | 2-30 | 2-30 | 2-30 | 2-30 | 2-30 | 2-30 |

Max.Diameter of Grinding Wheel(mm) | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

Total Power (kw) | 16 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |