Glass Loading Robot

- KING TECH

- CHNA

- 15-25 DAYS

- 50 SETS/MONTH

CL series sucker: the action is 90 degrees vertical rotation. It is used for vertical surface handling and rotation of various vertical glass deep processing machines, such as hollow glass production line, vertical drilling machine, straight edge machine and other vertical equipment upper and lower working sections.

Glass Loading Robot

Instroduction

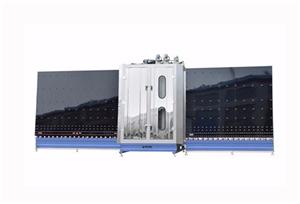

Vertical rotary sucker

KT-GL-250/350KG

Features

CL series sucker: the action is 90 degrees vertical rotation. It is used for vertical surface handling and rotation of various vertical glass deep processing machines, such as hollow glass production line, vertical drilling machine, straight edge machine and other vertical equipment upper and lower working sections.

Horizontal overturning sucker-arc glass

KT-GL-350/500KG-4/6B

Features

EL Series Sucker: The action is to turn 90 degrees horizontally. Horizontal handling process and turnover of various horizontal glass deep processing machines, such as tempering furnace glass production line, glue clamping line, bilateral grinding and other horizontal equipment upper and lower working sections.

Horizontal overturning sucker

KT-GL-150/250/350/500kg

Features

EL Series Sucker: The action is to turn 90 degrees horizontally. Horizontal handling process and turnover of various horizontal glass deep processing machines, such as tempering furnace glass production line, glue clamping line, bilateral grinding and other horizontal equipment upside and downs.

Electric sucker

KT-GL-P Series: PL/PEL/PCL/PCEL

300kg/500kg/800kg/1000kg

Features

PL series sucker: 220 V current drive, vacuum pump adsorption, for all kinds of horizontal and vertical processing machine vertical rotation, turnover handling processes, such as: hollow, sandwich, vertical drill, steel, vertical cleaning machine, packaging, fragmentation, etc.

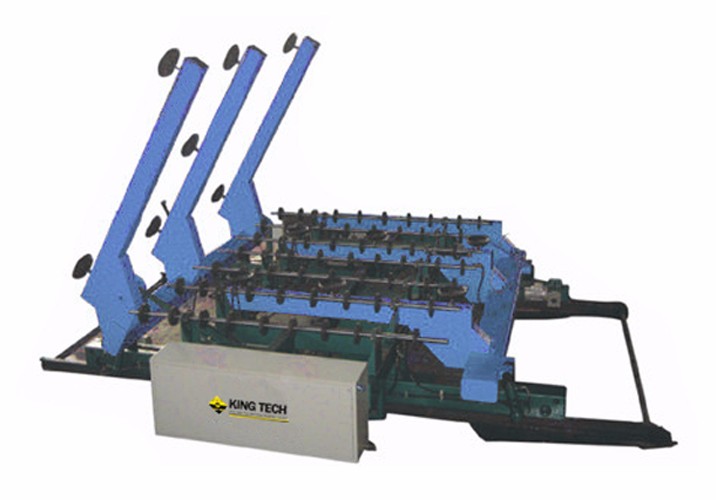

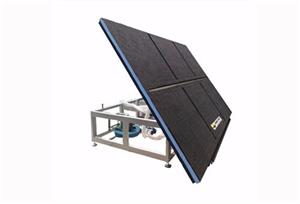

KT-GL-T Series Loading/Unloading Table

Features

This machine is mainly used for loading and unloading flat glass, insulated glass and laminated glass. It can unload the glass from glass racks via hydraulic and vacuum system. Glass can be sent to the production line through the transporting system. Its features are accurate glass positioning, steady turnover speed, safe and reliable operation.

Technical Parameters

Model | Max.Turnover Glass Size(mm) | Max. Turnover Glass Weight(kg) | Turnover Angle(°) | Total Machine Size(mm) | Motor Power(KW) | Weight(kg) |

KT-GL-T6032 | 6000×3200 | 1100 | 100 | 6100×3450×1000 | 4.5 | 2700 |

KT-GL-T6025 | 6000×2500 | 1000 | 100 | 6000×2500×1000 | 4.0 | 2000 |

KT-GL-T3825 | 3800×2500 | 600 | 100 | 3900×3000×1000 | 3.0 | 1500 |