Two-component Silicone Pump

- KING TECH

- CHINA

- 15-25 DAYS

- 50 SETS/MONTH

KT-SP Two component Silicone pump is the production of IG unit curtain wall to play with aluminum spacer, sealed in the realization of A,B groups were mixed.

Particularly suited to the requirements of the ratio of precision plastic kind of harsh for doors and windows and walls of glass deep processing enterprises efficient, high-quality, high pass rate of the production line operating needs.

The silicone pump broke through the traditional structures. Rack used welding as a whole, the increase in the gantry, welding triangle pose a stable structure, work to over-come the cantilever shake; B double-pump column, two-platen sealing Road, and solve the group were easy to glue oxide leakage problem; optimizing control Road design, to keep fast flow of similar products.

KT-SP Series Two-component Silicone Extruding Pump

Introduction

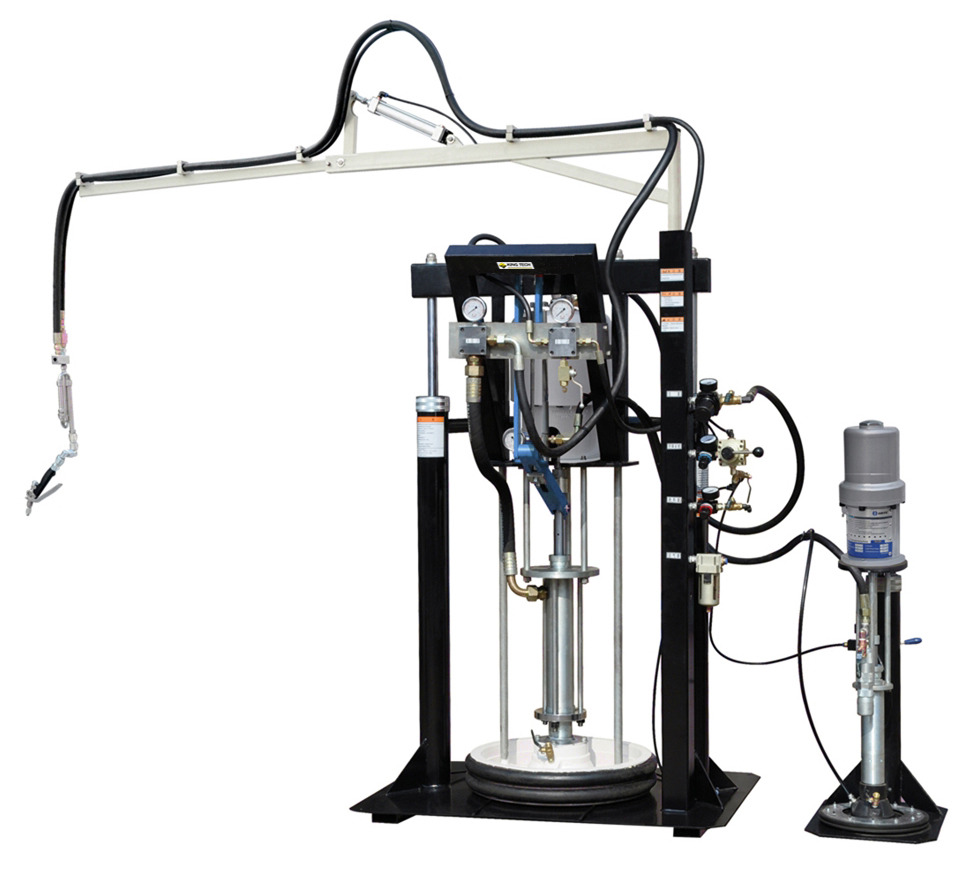

KT-SP01 Bi-component Silicone Rubber Extruding Machine(Pneumatic Type)

Features

KT-SP01 is Pneumatic style two-component silicone pump.

The silicone pump normally working with rotated sealing machine on production.

Technical Parameters

Size | 1100*950*1630 mm |

Weight | 650 kg |

Volume of Part A | 200 L |

Volume of Part B | Volume of Part B:20 L |

Mixing Ratio Range | 6:1—14:1 |

Max Air Consumption | 1.0 m3/min |

Maximum Squeeze Pressure | 25 MPa |

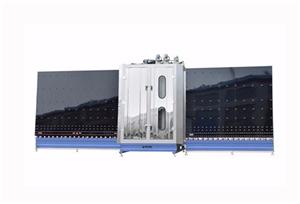

KT-SP02 Bi-component Silicone Rubber Extruding Machine(Hydraulic Type)

![]()

Features

KT-SP02 is Hydraulic style two-component silicone pump.

The silicone pump normally working with rotated sealing machine on production.

Technical Parameters

Size | 1420*850*1860 mm |

Weight | 650 kg |

Volume of Part A | 200 L |

Volume of Part B | Volume of Part B:20 L |

Mixing Ratio Range | 6:1—14:1 |

Max Air Consumption | 1.0 m3/min |

Maximum Squeeze Pressure | 25 MPa |